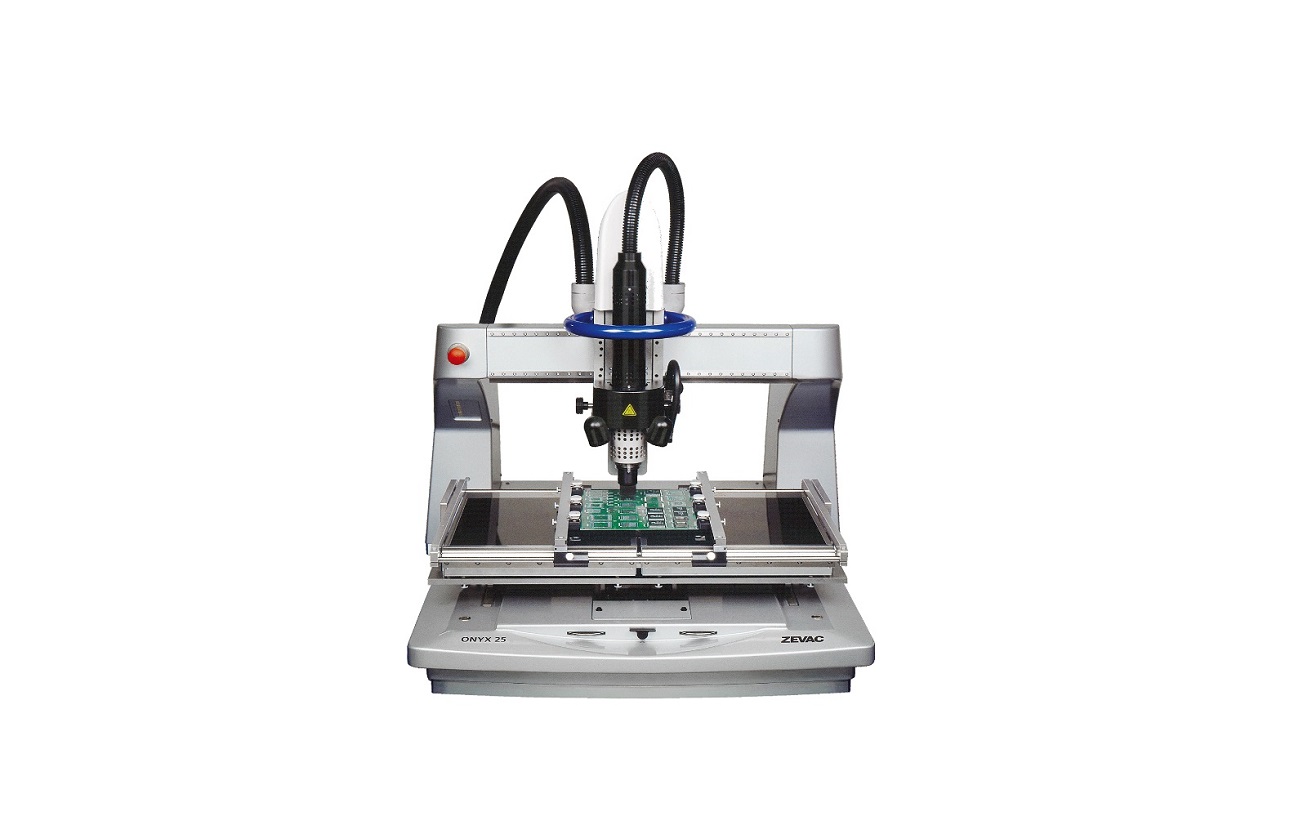

Description: ZEVAC ONYX 25 is used for repairing printed circuit boards with a width of up to 560mm. Due to the integrated visual system, precise rework of components can be ensured. The multifunctional heating system can be used for welding components, removing components, and on-site cleaning processes (non-contact removal of residual solder). The ONYX 25 benefits from its high mounting accuracy of<10 μ m, integrated mounting pressure testing function, and 4-axis electric control, ensuring high reliability and quality for continuous maintenance operations and other applications. ONXX 25 adopts an open design structure, and the length of the circuit board to be repaired is not limited. The system adopts the closed-loop VisualMachines application software, which can be used in highly complex production processes with simple parameter control and high repetition.

Scope of application

Precision repair of components such as SMDs, BGAs, uBGAs, CSPs, QFNs, QFPs, PLCCs, SOLCs, Flipchips, etc. in lead/lead-free processes, including mounting, soldering, desoldering, and soldering.